Porous Plastics Custom Prototyping and Production.

In-house, rapid response tooling for Industrial, Medical and Life Science clients.

Let's talk - Send a message

In-house, rapid response tooling for Industrial, Medical and Life Science clients.

Let's talk - Send a message

M.A. Industries' Porous Plastics Division manufactures open-celled, porous components for global markets, divided into two main segments. The Industrial Porous Plastics line, in operation for over 40 years, uses polypropylene and polyethylene to create products like lead-acid battery vents and mufflers. Separately, the Life Science segment manufactures in a controlled environment to produce high-volume, specialized items like pipette tip filters and IV Cannula Vents. For all products, M.A. Industries utilizes an in-house CNC machine shop to quickly turn designs into production and maintains a family-owned structure that grants customers direct access to key personnel.

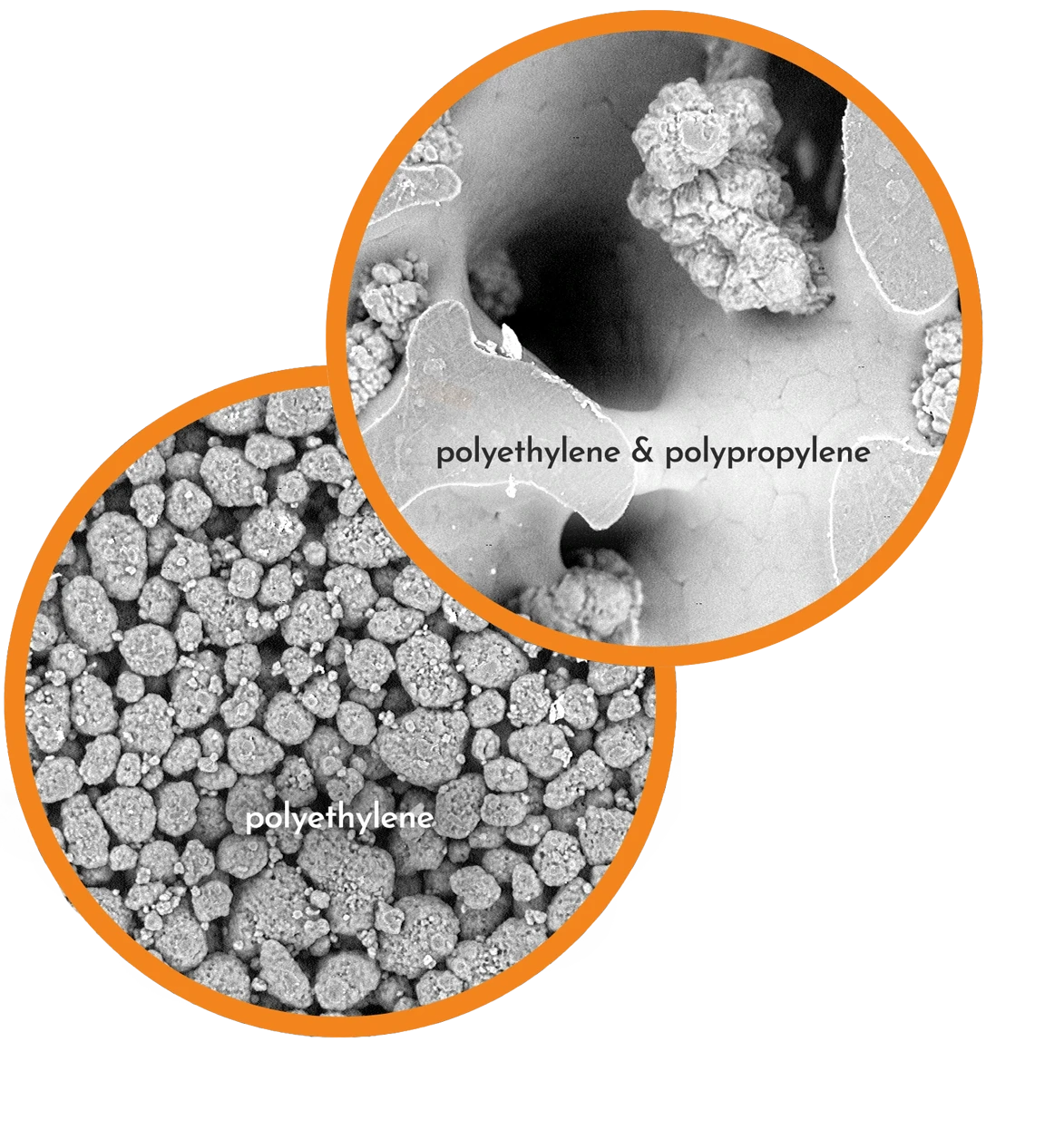

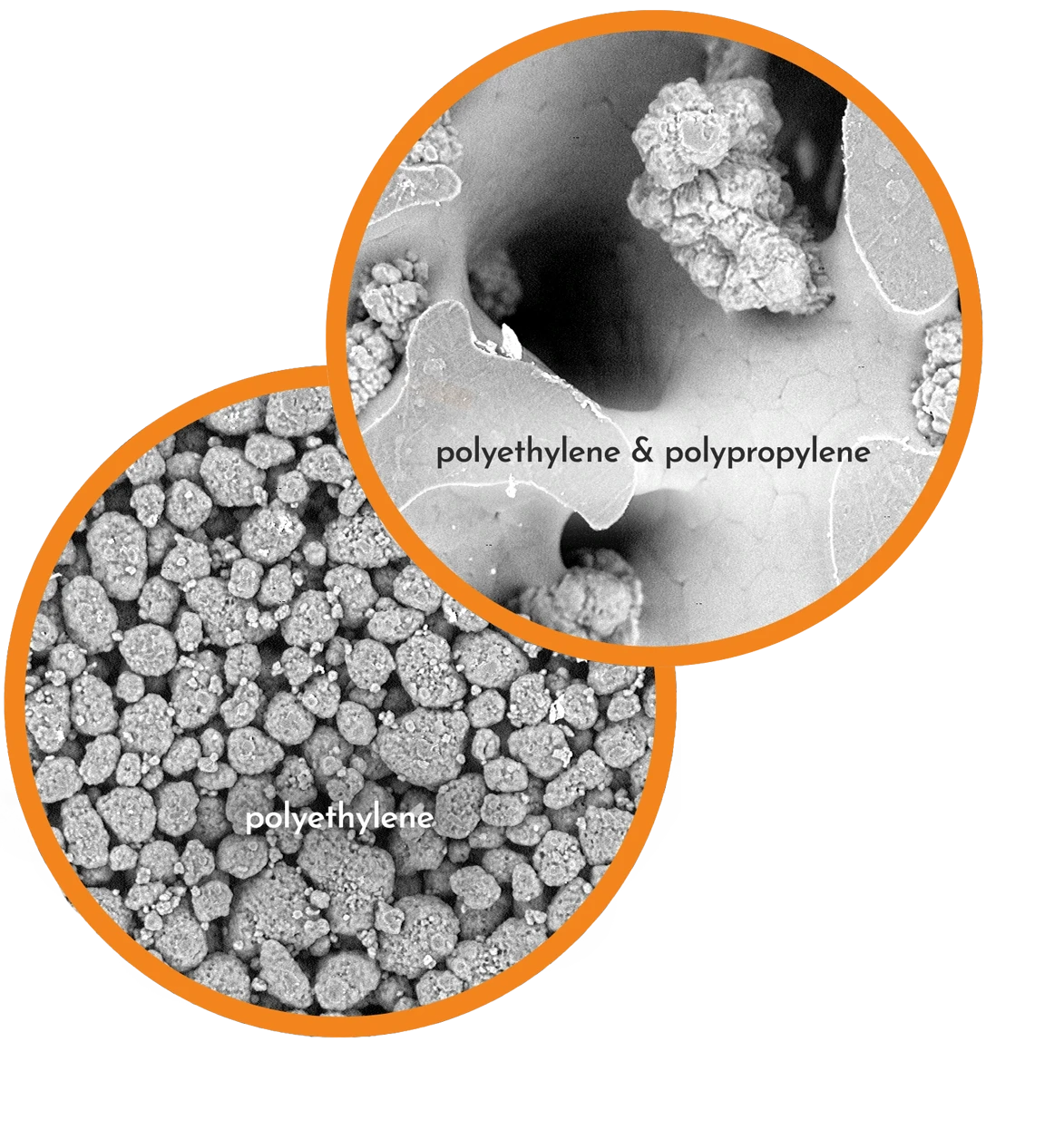

Company ProfileCryogenic Resin Grinding allows for optimum engineering of the raw materials for your products. Our products are manufactured from the industrys finest raw materials including:

The continual advancement of our Porous Plastics Division began with the flame arrestor in the lead acid battery industry with the molding of polypropylene and has now expanded into the consumer, medical and life science industries.

ISO 9001: 2015 certified by Underwriters Laboratories since 2003.

ISO 9001:2015 Cert #900:2015

10000470 QM 15

View ISO Certificate

We manufacture in- house all our prototype and production tooling allowing us a rapid response to any customer needs or requirements

We are committed to the Six Sigma and Lean Manufacturing Continuous Improvement processes.

The unique structure and performance of porous plastics combined with the filtering properties of activated carbons provide for unique filtration capabilities that are being employeed for water filters around the world.

M.A. Industries pipette filters provide the necessary protection from aerosol contamination critical in the life science industry. Our proprietary manufacturing process and resin blends ensures the highest quality and performance. Packaged and inspected in controlled manufacturing environments, our filters have been certified to be free of human DNA and RNase

The continual advancement of our Porous Plastics Division began with the flame arrestor in the lead acid battery industry with the molding of polypropylene and has now expanded into the consumer, medical and life science industries.

Industrial Porous PlasticsWe have extensive experience in manufacturing.

We have crafted custom solutions.

We supply porous plastics around the world.

We streamline to meet your needs.